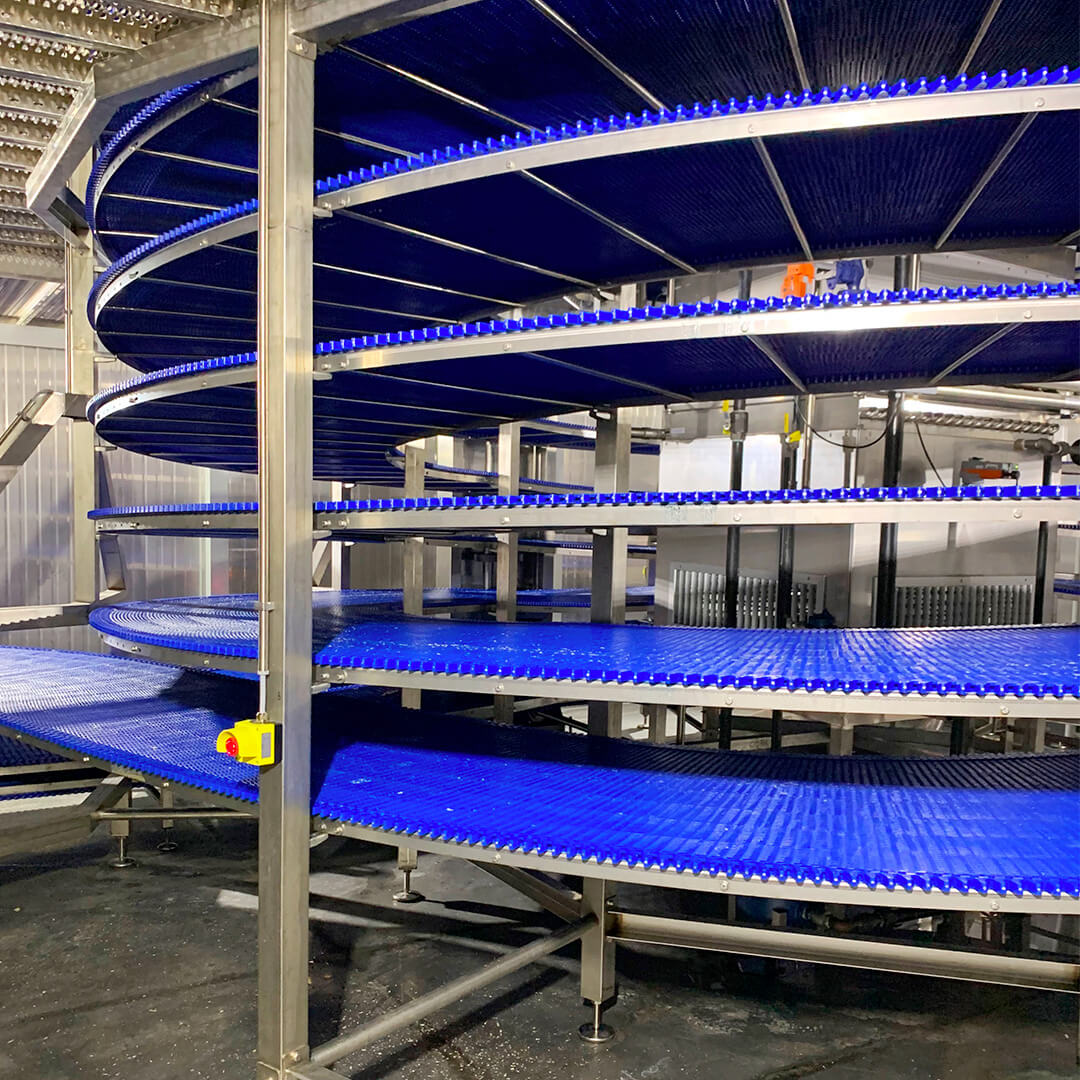

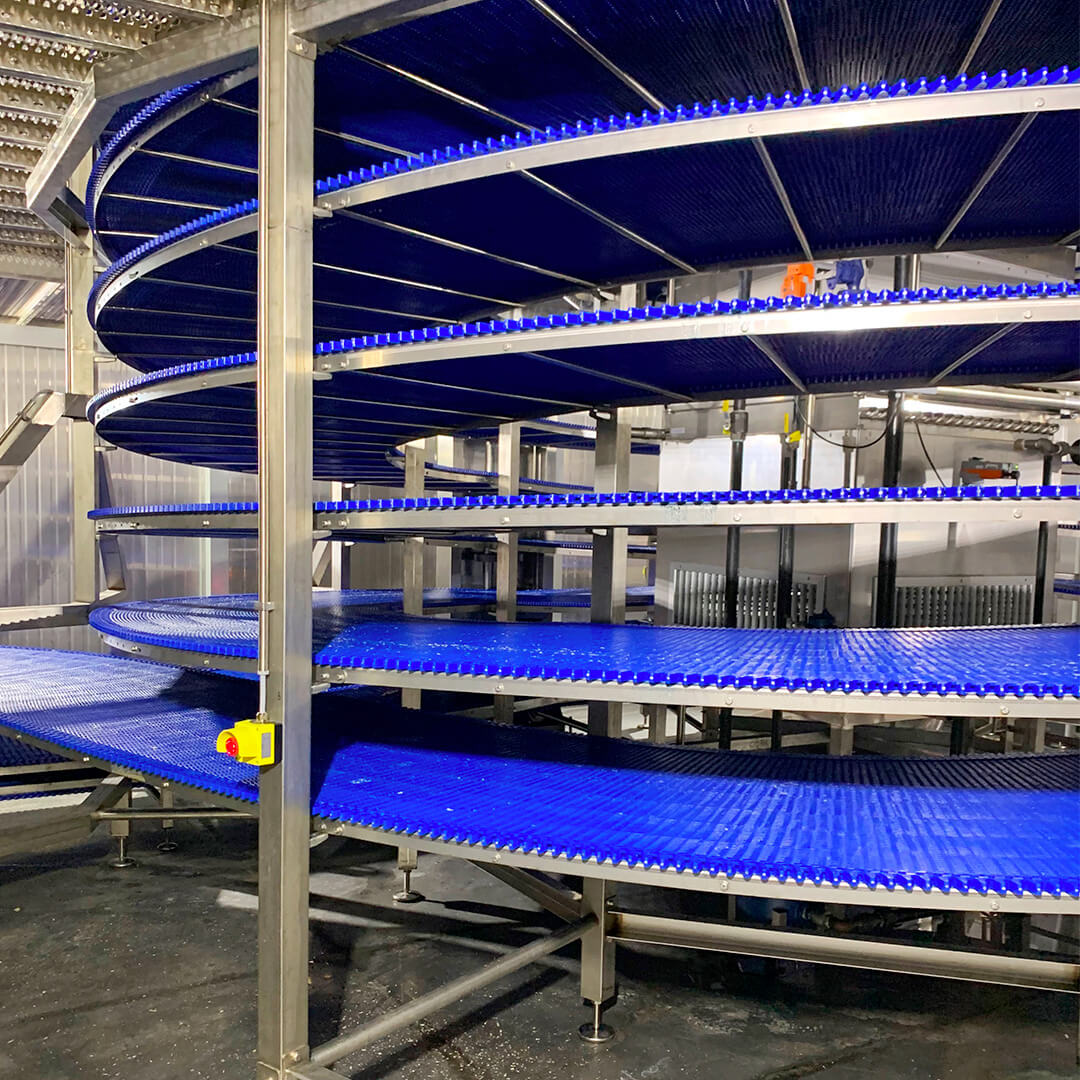

Spirals

Spiral Systems for thermic treatments

See other pictures

Our spiral systems for the thermic treatments involved in the production phases of food products are technologically advanced, versatile and reliable. Spirals maximize production performance during leavening processes, cooling and freezing, optimizing space.

Minimizing space, increasing energy savings and optimizing the sanitation and maintenance processes of the machine are just some of the features of our food spirals that guarantee the development of fully automated systems.

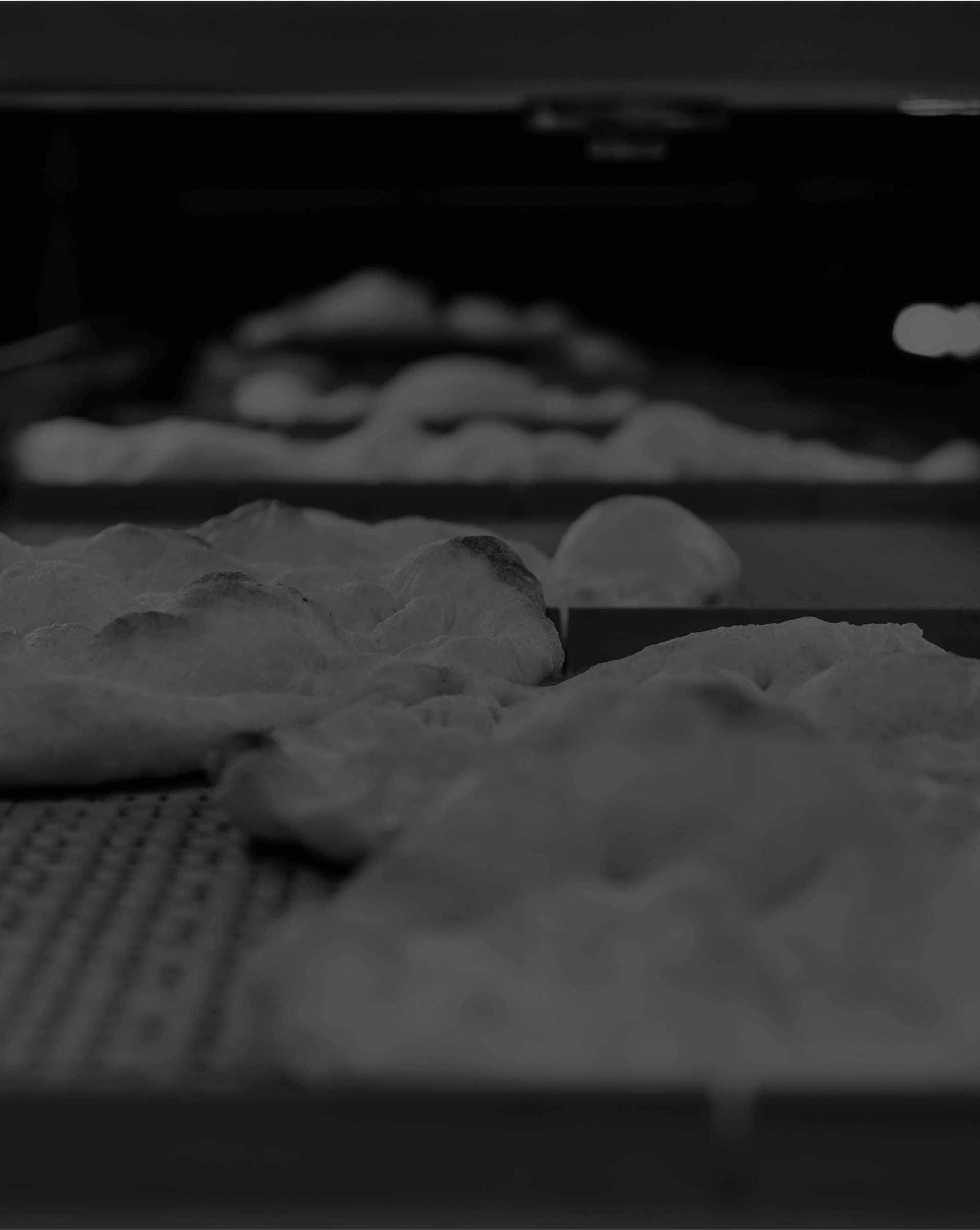

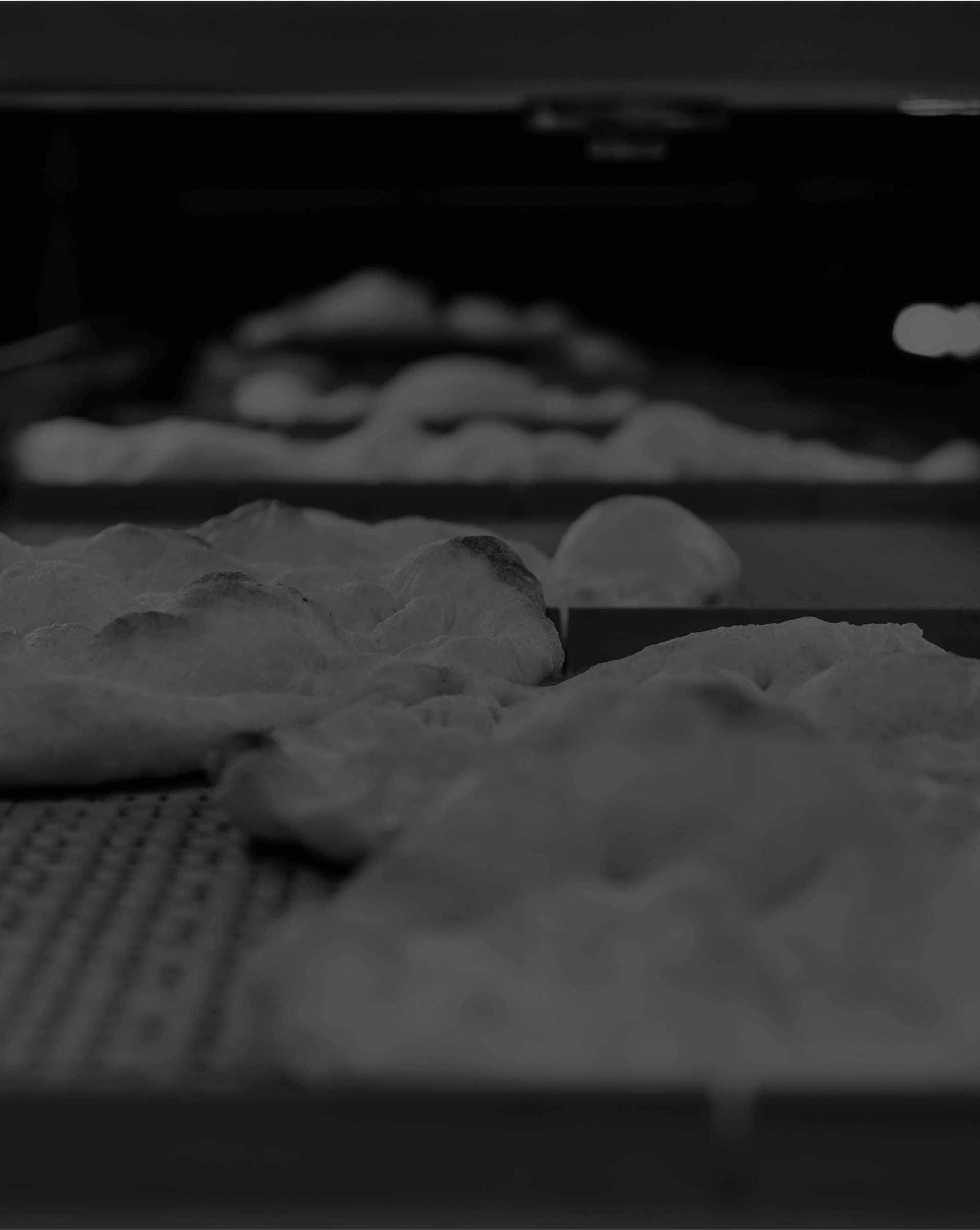

PROOFING

Our spirals are designed to maintain the organoleptic qualities of food unaltered during the leavening processes, ensuring total control of humidity, temperature and air flow levels. In particular, the VK31 belt, sliding smoothly, allows to respect the natural method of leavening of the product.

COOLING

The cooling processes are another use of our spiral systems for the food industry, which can be used both for the type of cooling in the environment, and in the cold room by means of forced and filtered air through the insertion of chillers and ATUs. Our solutions guarantee excellent performance and allow maximum control of fundamental parameters such as temperature and air flow.

FREEZING

We supply state-of-the-art freezing systems that allow maximum control of product freezing. In particular, our solutions inserted in an insulated room, specially designed to optimize the air flows created by the evaporators, make it possible to prolong food storage.

VK31 SPIRALS

We have an international patent for the construction of spirals with external drive which, guaranteeing low coefficients of friction and wear, allows obtaining a quality product in a highly sanitized context.

Each spiral is designed starting with the production requirements advanced by our customers and represents an extremely versatile solution, which can be used in leavening, cooling and freezing processes, and for insertion in the room. Food can be transported in bulk, packaged or in special containers.

FEATURES

Materials and Sliding:

The VK31 tape, tested and patented by Vimek in acetyl resin, provides various options for different types of products. The belt runs on a plastic anti-friction profile fixed on stainless steel guides.

Structure:

The structure of the VK31 spiral is made of stainless steel and equipped with adjustable feet for settling any unevenness in the floor. The structure is sturdy, designed for easy maintenance and cleaning. This special type of structure has been designed to minimize space, by inserting the temperature control unit in the center of the spiral, in order to also ensure a homogeneous air flow.

This solution can be used for leavening, cooling and freezing processes.

Single-motor Drive:

The drive unit is composed of a gear motor, stainless steel shafts, steel adjustable supports and plastic gear wheels to transmit motion to the chain.

Sensors:

The spiral mounts a capacitive sensor on each level to prevent any problems, responding quickly to any inconvenience. In addition, if requested, a product height control sensor is installed at the entrance to the spiral.

DRUM SPIRALS

The drum spirals consist of a commercial conveyor belt and equipped with a cylindrical-shaped towing system called, in fact, a drum.

This solution is designed to minimize the footprint. Food can be transported in bulk, packaged or in special containers.

Sturdy and durable, our drum spirals can be used for continuous work cycles and in extreme conditions of temperature, speed and product load.

FEATURES

Functioning:

The central drum transforms the dynamic friction force generated by the belt under pressure on its external surface from dissipative to conservative force, allowing the belt to move.

Structure:

The structure of the spiral is the part on which the drum is housed and on which the columns supporting the curves are fixed, which support the belt that winds around the drum itself. A sliding guide in plastic material with very high density and low coefficient of friction is fixed above the curves.

Do you want more information?